Warehouse rack maintenance

Powered by industry-first cloud based software THEIA, our maintenance packages cover the whole racking lifecycle from inspections to repairs to keep your warehouse safe, compliant and operational.

Reading endless inspection reports, identifying issues and arranging repairs can set you back weeks.

Not to mention lead times for new parts to arrive. All time you can’t afford to lose when damaged units could fail at any moment.

When you’re running a tight ship, any disruption to operations means lost earnings and missed targets.

The longer issues remain, the further you have to dig into your repairs budget to get back up and running.

Closing down locations is every Warehouse Manager’s worst nightmare.

And when you’re playing catch-up for months, you soon realise that maintenance is not a problem to be ignored.

Reduce downtime and maintenance costs by monitoring your units to catch issues before they become headaches.

Get an instant overview of your warehouse health with full traceability of issues and repairs for complete peace of mind.

Upload your old SEMA reports and our system will process them too, so you can prioritise and act fast.

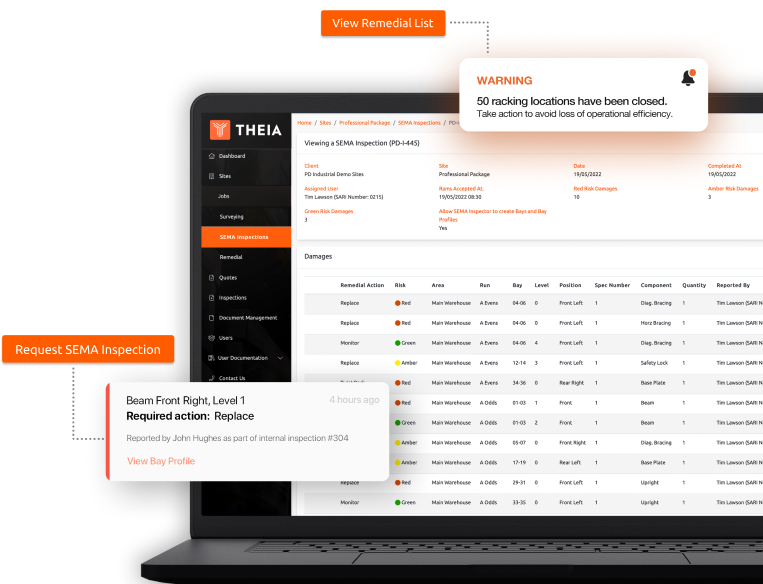

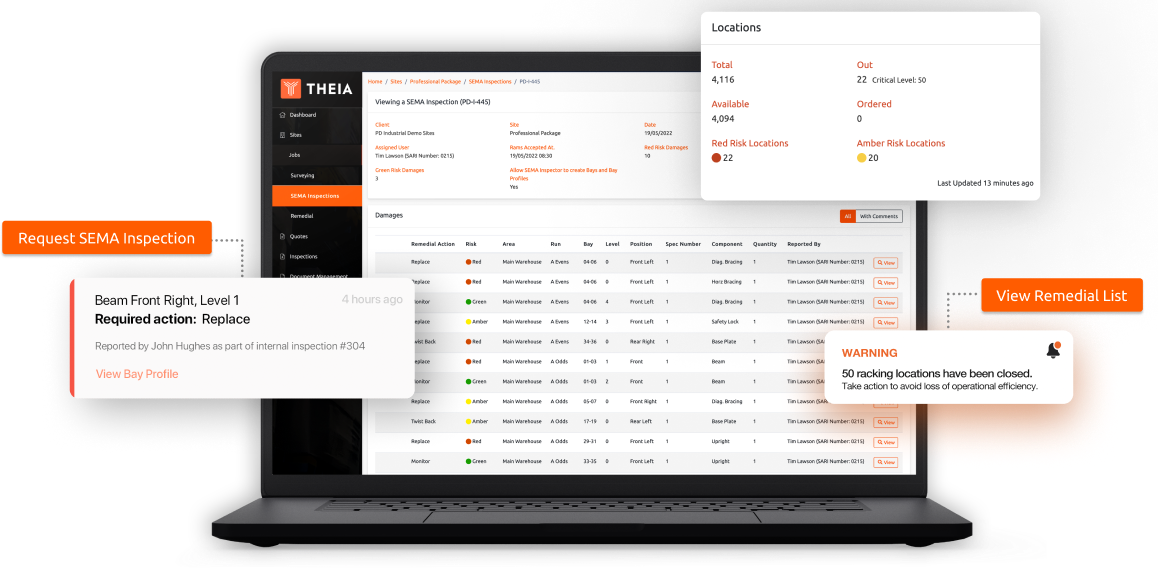

Our industry-first cloud based software revolutionises warehouse racking inspections and repairs.

THEIA shows you a virtual map of your racking health in real time, with a traffic light system to quickly prioritise issues, close affected locations and assess your overall operational capacity at a glance.

You can even enter rack view for a closer look at each issue in detail down to exact part number.

*Available with our Professional package.

Not only does THEIA record new inspections in the cloud, but it can also import existing and historical SEMA inspection reports and display them on a user-friendly dashboard.

No more digging through piles of paperwork for the information you need. Now you can see your warehouse health at a glance and book in repairs at the click of a button.

THEIA can be configured to your exact requirements. Set parameters for critical outage warnings based on your operational requirements and business needs.

You’ll get notifications delivered straight to your inbox or mobile app letting you know when issues before they get out of hand.

The Thiea system has made racking repairs far

easier to track and arrange.

The design incorporated all aspects of the brief, within the required timescales, and was adjudged to be the most professional approach.

“PD Industrial have been brilliant from planning to execution. They managed CDM with no issues whatsoever. Phil looked after and orchestrated the 8 different contractors to ensure there was no downtime”

© PD Industrial 2024

Website by Kensa Creative